What Causes First Round Pop in Suppressors?

For many firearm enthusiasts and professionals who use suppressors, the phenomenon known as “first round pop” (FRP) is a familiar but often misunderstood occurrence.

This effect, where the initial shot through a suppressor is noticeably louder than subsequent shots, can be frustrating for shooters seeking consistent sound suppression.

Understanding the science behind FRP can help shooters better manage their expectations and potentially minimize its impact.

The Science Behind First Round Pop

At its core, first-round pop is primarily caused by oxygen within the suppressor when the first shot is fired. Before the initial shot, the suppressor is filled with ambient air containing approximately 21% oxygen.

When the first round is fired, the high-temperature propellant gases rapidly mix with this oxygen-rich environment, creating an additional combustion event inside the suppressor. This secondary combustion produces extra noise beyond what would typically occur during suppression.

The Role of Temperature and Pressure

Temperature plays an important role in the FRP phenomenon. The extreme heat generated by the burning propellant gases, often exceeding 2,000 degrees Fahrenheit, creates ideal conditions for the residual oxygen to combust.

Additionally, the sudden pressure increase within the suppressor’s chambers contributes to the intensity of this reaction. After the first shot, the oxygen is largely consumed and replaced with inert gases, which is why subsequent shots are typically quieter.

Design Factors and Their Impact

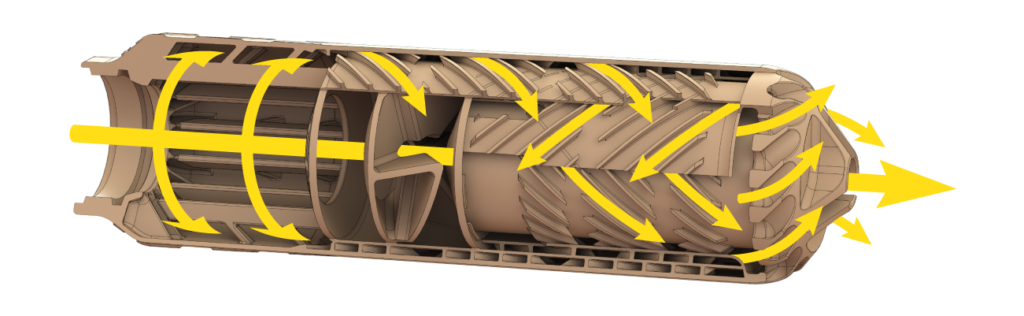

Suppressor design significantly influences the severity of first round pop. Larger volume suppressors typically experience more pronounced FRP due to the greater quantity of oxygen present in their internal spaces.

The number and configuration of baffles, expansion chambers, and other internal geometries can also affect how the gases mix and combust during that critical first shot. Some modern suppressor designs, such as the Thunder Beast DOMINUS-SR, incorporate features specifically intended to minimize FRP, though completely eliminating it remains challenging.

The Ammunition Factor

The type of ammunition used can significantly impact the intensity of first round pop. Ammunition with faster-burning propellants tends to produce more pronounced FRP than slower-burning powders. This is because faster-burning propellants create more favorable conditions for secondary combustion within the suppressor.

Subsonic ammunition generally produces less severe FRP compared to supersonic loads, as the lower pressures and temperatures involved reduce the likelihood of aggressive secondary combustion.

High-pressure calibers, such as .223, 6.5 Creedmoor, or 6ARC, will also typically have more first round pop due to the greater muzzle pressure quickly and violently expanding, combusting, and expelling the oxygen inside the silencer.

Practical Implications for Shooters

For most recreational shooters, first round pop is more of a curiosity than a serious concern. It is still hearing safe in hunting environments. However, FRP can be a more significant issue for military, law enforcement, or other tactical applications where sound signature is critical.

The increased volume of the first shot could potentially compromise stealth in sensitive situations. Understanding this limitation helps operators better plan their approaches and equipment selection for specific missions or scenarios.

Minimizing First Round Pop

While completely eliminating FRP is generally not possible with current technology, several techniques can help minimize its effects. Some shooters simply “preload” their suppressors by firing a single shot before beginning their primary shooting session, accepting the initial pop in exchange for consistent performance afterward. The second common method is to shoot the suppressor “wet.”

Shooting wet refers to using a liquid or gel substance inside the suppressor; water or wire-pulling gel are typically used. The liquid takes up some volume, but more importantly, it flashes to steam upon combustion, which helps to counteract the burning and expanding oxygen.

NOTE: Only low-pressure rounds, such as pistol caliber silencers, should be shot wet. A minimal amount of liquid, usually about a water bottle cap full, is all that is needed.

Environmental Considerations

Environmental conditions can affect the intensity of first round pop. Higher humidity levels can actually reduce FRP severity, as water vapor displaces some of the oxygen in the suppressor. Temperature and altitude also play roles, with colder temperatures and higher altitudes potentially leading to more pronounced FRP due to denser air and different oxygen concentrations. Understanding these factors can help shooters anticipate when FRP might be more noticeable.

Time Since the Last Shot

How long does it take for a suppressor to refill with air and cause another FRP? Usually, as long as the can is hot, you will not experience FRP. However, if you take a break from shooting and set the gun down for 10-15 minutes, allowing it to cool to ambient temperatures, you’ll likely experience another first-round pop.

Maintenance and Long-term Effects

Suppressor maintenance becomes more important when considering FRP. Carbon and other debris buildup can affect the internal volume and gas flow characteristics of the suppressor, potentially influencing FRP intensity.

However, it’s important to note that normal carbon buildup from regular use typically doesn’t significantly impact FRP, as the phenomenon is primarily driven by oxygen presence rather than suppressor cleanliness.

Future Developments

The suppressor industry continues to research and develop solutions to minimize first round pop. Some manufacturers are experimenting with new baffle designs and gas flow patterns specifically engineered to reduce FRP.

Others are investigating novel materials and coatings that might help mitigate the secondary combustion effect. While a complete solution remains elusive, incremental improvements continue to emerge.

Professional Perspectives

Many professional shooters and instructors have developed their own techniques for managing FRP in practical applications. Some advocate for specific loading procedures or suppressor preparation methods, while others focus on tactical approaches that account for the louder first shot. These experienced perspectives provide valuable insights for both new and experienced suppressor users looking to optimize their setups.

Wrapping Up

First round pop remains an inherent characteristic of current suppressor technology, rooted in basic chemistry and physics.

While it can be managed and minimized, understanding its causes helps shooters set realistic expectations and develop appropriate strategies for their needs.

As suppressor technology continues to evolve, we may see further improvements in FRP reduction. Still, for now, it remains a familiar aspect of suppressed shooting that requires awareness and adaptation rather than frustration.

Read the full article here